Automobile parts manufacturer

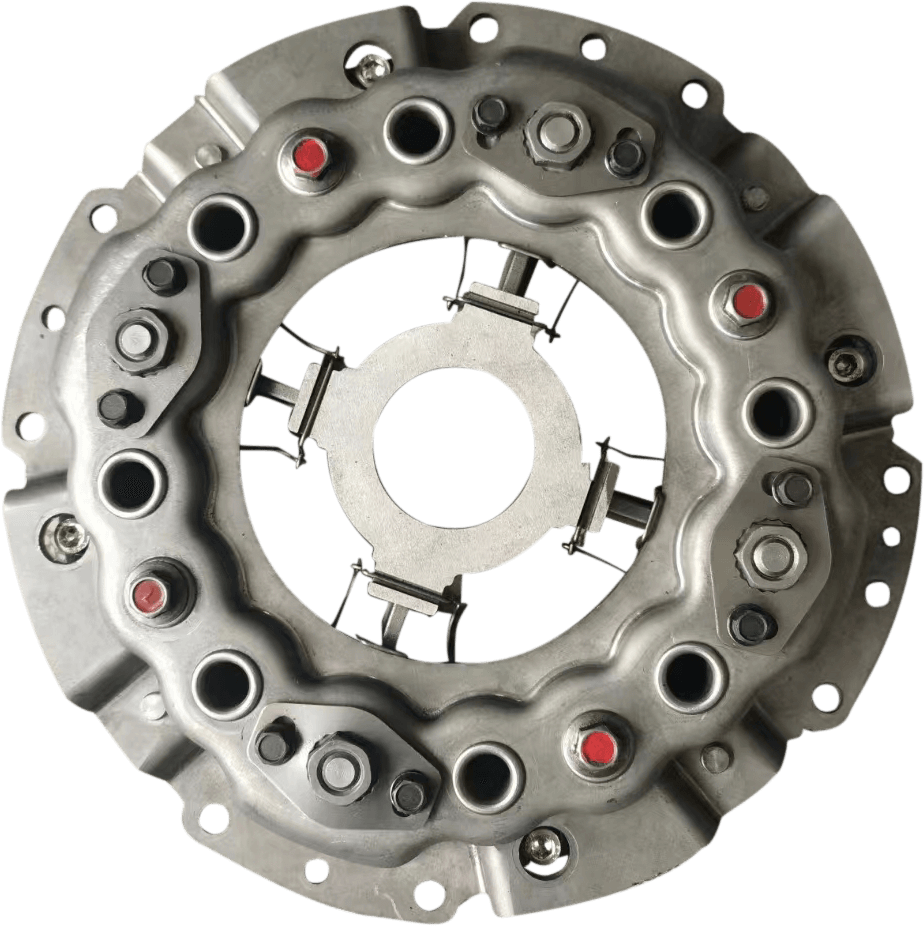

During the use of a car, it is inevitable that there will be some major and small malfunctions. For some small problems, if there are any, you can solve them immediately. The problem with the clutch pedal is one of the common fault phenomena: when the engine is idling, although the clutch pedal has been fully pressed, it is difficult to shift, and there is a knocking sound from the transmission gear. After reluctantly shifting into gear, the clutch pedal has not been released and the car has been driven or stalled.

There is no need to panic at this time, you can check it yourself. First, remove the clutch bottom cover, shift the transmission into neutral, and press the clutch all the way down. Then, use a screwdriver to move the driven plate. If it can be easily turned, it indicates that the clutch is well disengaged and there is no problem with the car's clutch accessories; If it cannot be moved, it indicates that the clutch is not fully disengaged.

Then start troubleshooting and solving the problems one by one: 1. Check if the free stroke of the clutch pedal is too large and adjust it. 2. Check if the height of the separation lever is consistent and too low. Move the release fork under the car to gently lean the front end of the release bearing against the inner end face of the release lever. Rotate the clutch for one turn to check. If the inner end of the release lever can not contact the release bearing at the same time, it indicates that the height of the release lever is inconsistent and should be adjusted. If the height of the separation lever is consistent and the separation is still incomplete, it is necessary to check the height of the lever. Adjust each separation lever to the same height. If it can be completely separated, it indicates that the adjustment was improper or excessive wear. After adjusting the release lever, the free stroke of the clutch pedal must be readjusted. 3. If the above adjustments are normal but the separation is still incomplete, the clutch should be removed and checked to see if the driven plate is installed backwards, if axial movement is difficult, if the main and driven plates are warped, if the release lever screws are loose, and if the floating pin is detached. 4. For clutches with newly riveted friction plates, check whether the driven plate and friction plate are too thick. If it is too thick, a gasket can be added between the clutch cover and the flywheel. 5. For hydraulic transmission clutches, in addition to the above inspections, it is also necessary to check for a lack of brake fluid, pipeline leaks, and exhaust air from the hydraulic system.

How about it? Do you think you have gained a lot after watching it? Many professional knowledge can be applied to practical situations, and some seemingly difficult problems can be gradually solved step by step. Although clutch failures are troublesome, they generally cannot escape the analysis of several reasons. Of course, for those who cannot handle it themselves, they can only go to a repair shop or a nearby 4S shop for repairs.

We would like to learn more about Our Products, Call me